Tinning is often referred to as the "poor man's" alternative to more expensive plating processes such as gold, platinum and palladium, due to

this post-transition metal's relatively low cost. However, this designation belies the significant value offered by tin plating. In addition to helping

to keep operating costs low, tin plating offers key benefits such as excellent corrosion protection, a high level of solderability and good contact

resistance.

ENHANCING THE EFFECTIVENESS OF TIN PLATING

Alloying tin with other metals can improve the results obtained with tin plating. For instance, alloying tin with nickel and cobalt improves

hardness, while a tin-zinc combination enhances corrosion resistance. When solderability is a primary concern, a tin-lead alloy can prove

beneficial, while a tin-silver alloy, still in the testing stages, has shown promising results for a variety of applications.

WHEN IS TIN PLATING USED?

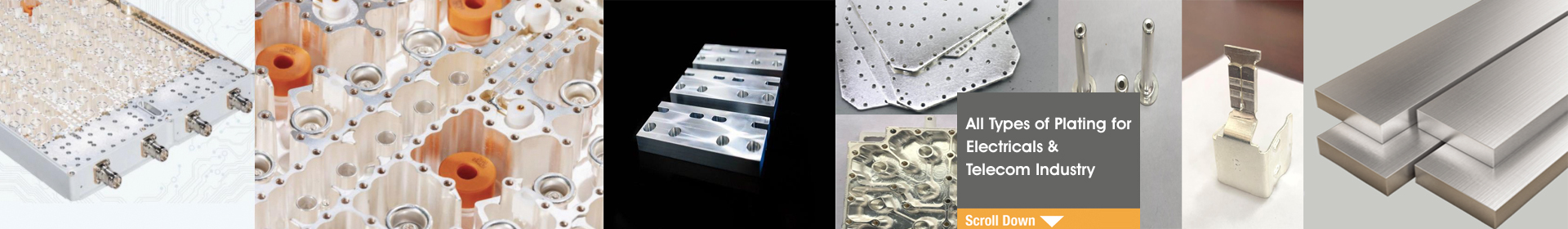

Speaking of applications, tin plating has many! Tin's ductility and non-toxic nature, as well as its corrosion resistance, makes it a top choice for

food service-related industries, particularly in the manufacturing of fast food equipment, as well as in the production of cookware. Electronics is

another industry in which tin plating is pervasive, primarily due to its ability to preserve solderability. As solar power continues to increase in

popularity, tin plating has carved out a significant niche in the housing industry.