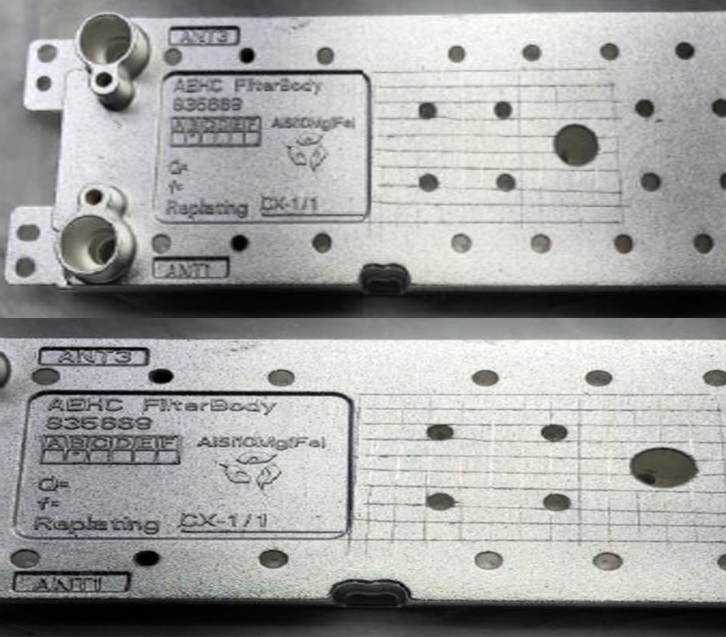

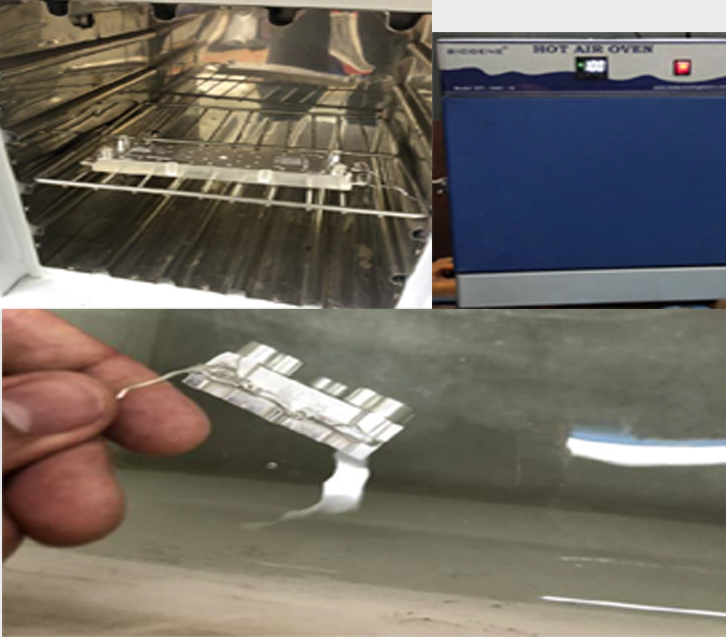

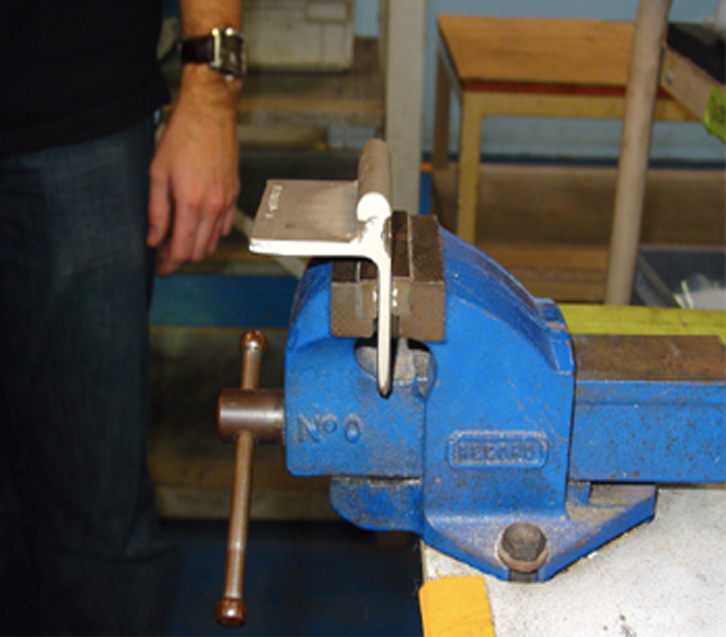

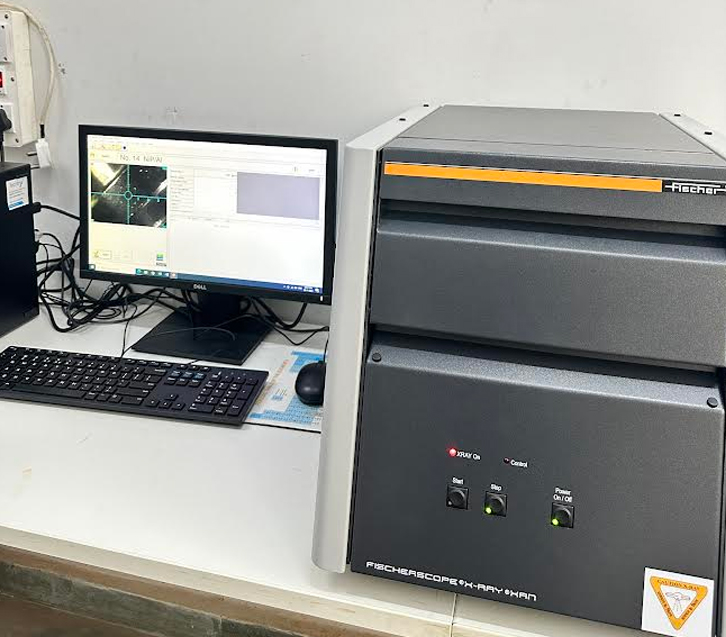

Thickness Test

Plating thickness is the most crucial part of our business, we work as per customer spec, also installed micrometer along plating baths to maintain the thickness For thickness test we have a Advance micro test thickness machine which can check various plating layers like- Silver, Gold, Tin, Copper, Electroless Nickel, etc.